Hundreds of thousands of empty containers are filling marine terminals and truck yards across Los Angeles and Long Beach ports. Most of these are stagnant on the vessels, and they are waiting in fast-growing lines at ports to get offloaded, meaning even more congestion and creating extreme bottlenecking throughout the supply chain. As a result, shipments have been delayed, exacerbating tensions within global supply chains—there is a heavily costly consequence.

This is a critical wake-up call because the maritime shipping industry is the backbone of world trade, and 80% of all goods are carried by sea. The industry is changing, and you cannot fight new wars with old weapons.

It is time to explore why predictive analytics matters and how AI can solve the port congestion problems.

Predictive analytics is vital for the shipping industry

Today’s digital world is all about data, introducing a new era of transparency in the shipping industry. By examining patterns in large amounts of data, predictive analytics provide insights that can lead to better-informed decisions. Even if the demand is growing, analyzing the demand based on seasonality, last year, and historical data provides forecasts.

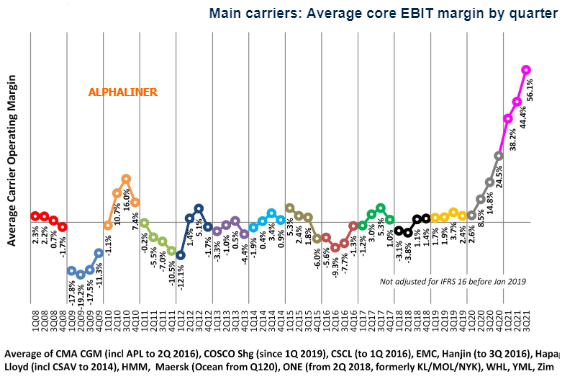

Despite the global shortage, Alphaliner counted 54 ships and 167,887 TEU as commercially idle, a drop of three units and a rise of 3,347 TEU in capacity when compared to the previous survey. The industry is desperate for more power to cover the needs.

It is essential for transportation companies to have a reserve of containers at ports that they frequent. However, the problem is that companies usually overestimate the numbers they will need. With AI forecasting, not only is the number of full containers more precise but an estimation of available empty containers is also procured. By doing so, data analytics can prevent companies from buying extra containers.

An AI optimization model takes all the costs that occur during the container lifecycle into account. Data analytics can provide visibility into the historical performance, health of current operations, and future costs based on predicted trends—showing whether a container should be express shipped or has time to wait in the port. This way, companies can decide to move empty containers back to high-demand locations in time of need, meaning that they can save on storage costs while minimizing empty stock imbalances.

Through predictive analytics, individual companies can gain more visibility into operations resulting in optimal levels of safety stocks. Moreover, it can help better delegate shipping demands with data authenticity and consolidation, allowing for cost optimization.

How AI is shaping predictive analytics

According to a survey by Navis, 83% of respondents expect to increase their investment in AI technologies because AI powers predictive analytics and is the perfect solution to deal with complex issues and operations because of its ability to consider numerous variables in real-time.

Every logistics or shipping company uses a transport management system that can offer enough data to optimize processes further. Nevertheless, one of the challenges here is data quality, as some of the records might be incorrect or incomplete. So, the first step is to apply the AI to see the gaps in the data—and to fill these.

Second, AI takes into consideration all the relevant data, not only historical but also external factors such as weather and holidays. AI algorithms can give you a better understanding of your operations. AI work is not telling you what to do. It is an aid for you to see the bigger picture. Then, you can start asking questions. ‘‘This is the number of containers that we have, but do we need all of them? Do we have them in the right location?’’ This is a partnership between human power and AI. Logistics planners are pilots, and AI is the co-pilot.

Asking the right questions with the guidance of accurate data helps companies to operate more efficiently, decrease operation and container management costs while keeping the same service levels, and perform well as a company.

The biggest shipping companies have already adopted AI algorithms to forecast the demand and ensure that it’s accurate. It essentially saves valuable time for the planners and for logistics operations—teams can spend the resources to focus on improving customer service excellence.