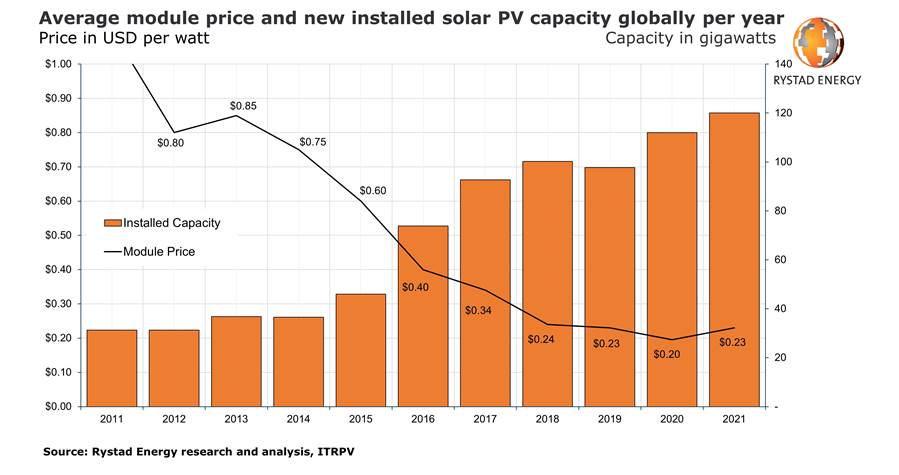

The cost of building solar farms has been declining for several years, making the renewable technology increasingly popular with projects of all sizes mushrooming around the world. The tide is now turning, however, as new utility PV projects are starting to become more expensive due to increasing costs for modules, shipping and labor, a Rystad Energy report reveals.

Rising commodity prices and shipping costs are eroding utility PV project margins, potentially leading to delays for developments nearing financial close. Modules account for the largest single capex item of utility PV projects, which means even modest changes in costs can lead to significant challenges for project economics.

One of the key commodities used in solar cell manufacturing is silver, as its electrical properties make it an ideal electrical contact to the front and rear of the cell. Between 2012 and 2016, the industry dramatically reduced the use of expensive silver from over 200 milligrams per cell to around 100 mg/cell.

The amount of silver used has declined only moderately since 2016, and currently lies in the range of 80-90 mg per cell – contradicting bullish predictions of industry bodies. By using less silver per cell, and also benefiting from the commodity price drop, the PV industry has seen the contribution of silver’s cost per watt reduced from $0.05/Wp in 2012 to $0.015/Wp in 2020.

However, silver’s contribution to total module costs is now on the rise again as silver usage per cell has plateaued while prices are increasing. The PV sector represents 10% of global demand for silver, whereas the expected additional growth brought on by the automotive industry amid the rise of hybrid and electric vehicles could drive silver demand from this sector up from 51 MMoz in 2020 to 88 MMoz in 2025, pushing prices even higher.

On the supply side, mine production of silver has been falling since 2016. If prices climb to over $40 per ounce – a level last seen in 2011 – silver’s contribution to module cost could rise to $0.03/Wp. And silver is just one of several key commodities used in PV module manufacturing, alongside polysilicon, glass and aluminum – all of which have seen price increases over the past 12 months.

Historically, the cost of a shipment transport from China to key markets around the world has been $0.006/Wp, but in 2021, in the aftermath of Covid-19, it spiked to $0.02/Wp. This is another significant cost increase for PV developers as shipping now accounts for just under 10% of the cost of the module FOB (prior to shipping). As recently as 2019, this represented only 3%. While this increase could possibly be a short-term effect of the pandemic, Asian-centric module production means shipping cost will remain a key factor to watch for developments on other continents.

How higher module costs make projects more expensive

The rising costs will impact project economics significantly at high-capacity facilities that benefit from economies of scale. For a typical large-scale 100-megawatt (MW) utility PV project, a cost increase on a module from $0.18 to $0.24/Wp represents a 9% hike in project capex on a dollar-per-watt basis.

Furthermore, for modules that previously accounted for 25% of the project capex, their share of costs would climb to about 30%, thus increasing the project’s levelized cost of energy by $3/MWh. The implication of increased costs will be delays to projects nearing financial close as project margins shrink for developers, engineering, procurement and construction companies (EPCs) and original equipment manufacturers (OEMs).

Increasing wages add extra pressure

“The construction of a utility solar PV asset is labor-intensive and wages generally rise over time. In combination with increasing module costs, the mix is a perfect storm that can threaten the profitability of new utility solar PV projects, as the industry’s workforce is poised to play an increasingly larger part in the cost of developing assets,“ says Henrik Fiskådal, energy service analyst at Rystad Energy.

The share of capex spent on engineering, procurement, construction, and installation (EPCI) has increased over time compared to PV equipment costs. PV modules have historically been the largest single cost item for utility solar assets, but as module prices decreased, the relative cost of equipment dropped by 16 percentage points between 2016 and 2020.

However, building a utility PV asset requires an array of different skilled personnel such as construction workers, electricians, engineers, machine operators and logistics staff, in addition to the white-collar work related to the acquisition and legal preparation of the site. Much of this work consists of tasks that cannot easily be automated or scaled, and the solar industry will continue to depend on this labor for new projects.

Out of the top 10 countries lined up to make significant investments in the solar PV industry between 2021 and 2023, China and the US are expected to account for the largest share. The labor rates in these markets can help reveal the trends behind potentially increasing utility solar PV asset costs.

In the past five years, the compound annual growth rate (GAGR) for electrical equipment mechanics and installers has increased by almost 7% on an annual basis in China. While wage growth was stagnant in 2020 due to the pandemic, the Chinese government is determined to keep expanding its economy, which we believe will also lead to higher salaries.

Rystad Energy expects average Chinese wages to increase by over 20% from 2020 to 2023, as growth could also cover some of the slowdown brought on by the pandemic. Assuming the percentage between equipment and labor cost stays constant at today’s levels, this 20% wage increase could on its own boost the total cost of building a solar PV project by over 5% over the next three years.

To compare, Rystad Energy expects average wages in the US to grow by only 6% over the same period, which would translate into a 1.7% total cost increase for solar projects as a result of labor costs alone.