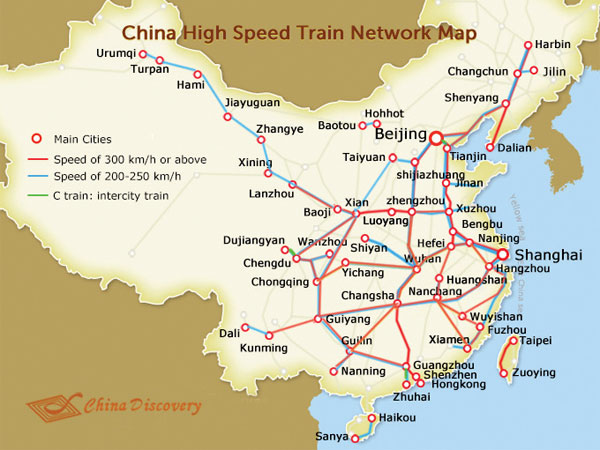

Over the past decade, the People’s Republic of China (PRC) moved into a leading position on the global stage by their construction of the high-speed rail (HSR) network. Their success is attributed in part to the Hanjiang Heavy Industry, Co., Ltd. (HHI) of the China Railway Construction Company. HHI manufactures, transports and operates 450-ton girder-hoisting machines applied to the hoisting, displacement and loading of the whole span of precast concrete box girders for the construction of the passenger HSR lines.

Over 15,000 miles of HSR

Travel times are reduced by hours from the older network and service levels are much higher. Beijing to Shanghai on the HSR is 5 hours from 12 hours (two hours by air) on the older network. China Railway Company service attendants are professionally uniformed and walk the aisles with food carts as well as sweep the aisles and maintain clean, modern restrooms. The passenger seats recline and are equipped with electrical outlets with folding seat trays. The travel experience is vastly different than the old train network of clanking cars and unsanitary conditions.

Situated near the Han River, an important defense fortification against the invading Mongols in the 13th century, and a tributary of the Yangtze River in Xiangyang, Hubei province is Hanjiang Heavy Industry, an important manufacturer to the largest HSR system in the world. Xiangyang has a long history as a central transport location for trade between the north and the south of China and HHI is ideally situated to serve the expanding national HSR construction. The company has four factories producing a variety of bridge construction equipment and girder transporter vehicles for rail and highway projects. Annual output is 400 sets and valued at $217.8 million (1.5 billion yuan).

“The products are shipped to all parts of the country according to the order, and exported to Singapore, Libya and South Korea,” said Mr. Li, Manager, Sales and Logistics, Hanjiang Heavy Industry Company in a recent interview.

Manufactured raw material inputs of steel are produced and sourced from nearby Wuhan city suppliers. These larger steel shipments have logistical problems since there are not many companies with large trucks to handle these shipments to the factory. “In one week, we need 5 trucks of 30 tons each and sometimes it is hard to find these specialized project cargo trucks,” said Mr. Wang, Inbound Purchasing and Logistics Manager, HHI. Project cargo truck permits are also a constraint and increases costs by delays to production schedules for HHI.

Inland Waterway Constraints

Inland water transport (IWT) would reduce transport costs for steel inputs to HHI. However, the Xiangyang river ports are not modern nor is there depth of the Han River in Xiangyang to navigate 1500 dead weight ton vessels. “Our steel suppliers are near capable Wuhan river ports, if we can use IWT, that would be useful to us for steel materials to reduce transport costs,” said Mr. Jiang, Director, HHI.

Putian city, Fujian province, along the eastern coast, will receive the newly produced “beam moving machine for the transshipment and erection of 40 meters long beams,” said Mr. Li. Two 450-ton beam-lifting machines are used together for the transshipment and erection of 900-ton concrete box girders as well as the bridge pier for the whole lifting of the 900-ton beam, he described. Putian city is one station on the north to south line from Hangzhou, Zhejiang province, near Shanghai, to Shenzhen, Guangdong province, near Hong Kong.

Hanjiang Heavy Industry is also challenged by the logistics and transportation of their new machines to customers such as to Putian city. The machines are disassembled into parts and placed onto trucks. There is a lack of cranes and logistics companies to do high quality services for HHI. “They are usually transported by trucks of 42.6 feet (13 meters) or 57 feet (17.5 meters). Each vehicle weighs 30 tons and transit time to Putian is about 2.5 days,” said Mr. Li.

The possibility of transporting the disassembled parts of the machines to customers in Fujian by IWT is lost because, “there is no cargo terminal in Fuyang, Xiangyang.” For now, if water transportation is required, then it needs to be transported by truck to Wuhan for water transportation. “The cost will increase and the transportation time will be extended. I hope the government will consider building a cargo terminal in Fuyang,” said Mr. Li. Numerous projects are under consideration and in construction to make better use of Xiangyang’s IWT system for project cargo shipments.