Tracking a shipment from factory to final destination is a complex affair full of technological traps and logistic pitfalls. But realtime shipment visibility is the key to managing a successful supply chain and Chicago-based FourKites has made a business out of pioneering realtime tracking.

For example, how do you keep tabs on one container that may be literally surrounded by 10,000 others in the middle of the Pacific Ocean? Or how do you track goods being transported from, say, the middle of China or India by a mom-and-pop trucking firm destined for a port located hundreds of miles away? Answer: Right now, you cross your fingers.

FourKites has made great strides doing just that. It has emerged as an industry leader in this new logistics-related field, which is not even a decade old. FourKites itself launched in 2014, first tackling trucking. It added ocean-going vessels in late 2017.

FourKites, itself, is only a software platform. The company, based in Chicago, works with more than 200 hardware providers.

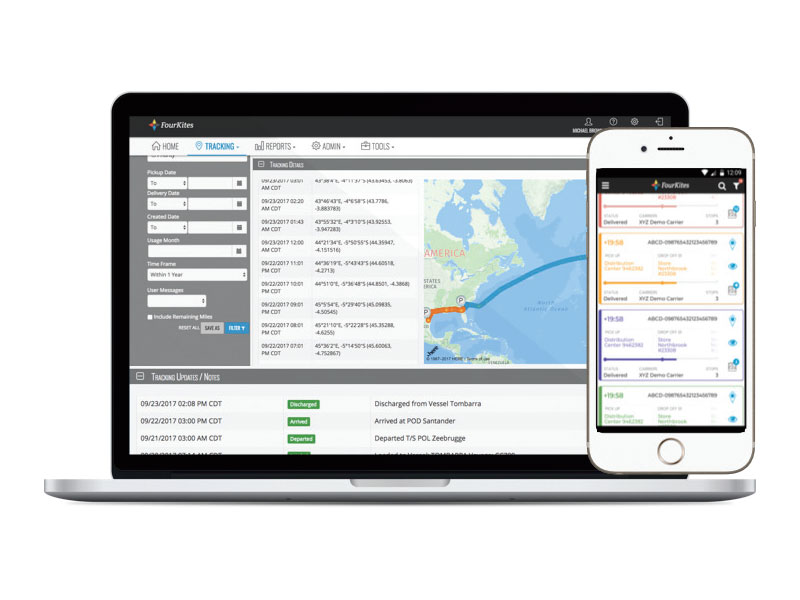

Its system works like this:A shipper or logistics provider buys FourKites software. It then instructs its transport operators, terminals and distribution centers to link their systems with that of FourKites. FourKites has the ability to integrate transport management systems, telematics, GPS systems, warehouse management systems, port management systems, yard management systems, and ERP (enterprise resource planning software).

“Think of us as a data aggregation platform,” said Elenjickal in an interview with American Journal of Transportation. “We collect data from all the companies and we create a single pane of glass for the shippers.”

Elenjickal cited The Kraft Heinz Co., an early FourKites client. The food behemoth uses well over 100 different transport companies to move its freight. In the past, the only way Kraft Heinz could keep tabs on the flow of its goods was to look at every transporter’s web site or have each transport company send data. Both alternatives created information logjams. Now, Kraft Heinz sends FourKites data from its own transport management system, which includes information on the companies transporting its goods, as well as whether the goods are being carried full or partial truckload or by containers. FourKites electronically contacts the operators and requests data on what vehicles are being used as well as access to those trucks’ tracking devices. FourKites can then monitor individual trucks, giving Kraft Heinz a near-constant update on where its goods are and when they’ll likely be delivered.

The Issue of Seeing Freight at Sea

Trucking firms must cooperate with FourKites to do business with Kraft Heinz or other clients because the shippers insist on it. “What we’re seeing is that FourKites is part of the contract the trucking companies sign with a shipper. “That’s like a new norm.”

Monitoring containers at sea is another matter. It’s still virtually impossible to track an individual container at sea. That’s because even if a container is armed with a GPS device, it needs a clear view of the sky to operate. So, shippers must rely on what a vessel is doing.

Shippers provide FourKites with the vessel operator, which communicates with FourKites the name of the particular ship transporting a container and whether the container is transshipped. FourKites monitors the ships.

Likewise, terminals and distribution centers are increasingly providing FourKites with shipment location and status data. According to Elenjickal, some 40 terminals, through their terminal operating system software, now connect with FourKites.

Elenjickal offered several examples of how this works. There are obvious ones: Weather reports, for example, indicate a storm is coming. FourKites can suggest a route change or an early pickup time.

Traffic is another obvious variable. According to Elenjickal, FourKites has accumulated enough data on certain routes to advise clients on when they should schedule pickup and deliver. “You can incorporate those benchmarks into planning so if you know that by starting at noon rather than at nine, you can have a better on time delivery percentage,” he said.

There are other possibilities. Elenjickal cited a study FourKites did for a client that revealed vessels on average arrived two days earlier than their posted arrival times. Understanding this allows shippers to schedule earlier pickups at ports, further streamlining the supply chain and cutting down on storage time and costs.

FourKites is connected in Europe, South America and South Africa, as well as in the US. This year, it is extending its reach to Southeast Asia. Rolling out its system there is no easy task, as most trucks lack embedded GPS locators. To overcome this technology gap, FourKites will offer a mobile app to drivers in local languages.

“We can get the location ping through the app,” said Elenjickal.

According to Elenjickal, trucking companies and distribution centers are beginning to see the value in FourKites and visibility software. In the past, a truck driver is scheduled to arrive at a distribution center. He could be early and forced to wait until a dock is available and the shipment is staged. Or he could be late, causing the warehouse to needlessly keep a slot open. With FourKites technology, “we can tell the location proactively, ‘this driver is going to show up in two hours. Make sure the dock is empty and the product is staged,’” said Elenjickal.

This improves productivity on multiple fronts and provides added benefits up and down the supply chain. It’s one reason why visibility software is here to stay and will only become more appealing in the months and years ahead.